Lower Woodburn WwPS

Challenge

Project delivery

Delivery partners for this project were appointed through existing NI Water frameworks. Tetra Tech was appointed to provide professional services, (including project management, cost management and site supervision) and to act as NEC Project Manager. The Murphy/ DAWSON-WAM Ltd JV (MDW) was appointed as main contractor.

Building on earlier work done to investigate catchment-wide solutions for Carrickfergus as part of the LwWP, MDW was engaged to develop the design and build solution under an Early Contractor Involvement (ECI) NEC contract. The design was reviewed and approved in collaboration with NI Water, and budgetary approval was granted for construction works under an NEC-ECC Main Option A contract in summer 2023.

Delivery was a collaborative effort between client, consultant and contractor teams to improve water quality and environmental conditions in the receiving Belfast Lough. The works comprised addition of surface water storage in a new concrete cofferdam constructed alongside, and connected to, the existing pumping station wet well. The constrained nature of the site lead to the need for access to neighboring lands from which to operate construction plant and machinery.

The scope was further developed during construction to improve the overall solution performance by installing a non-return valve on the storage overflow to enhance separation between storage and the marine environment and to improve the design life of the pre-existing pumping station.

Change was addressed using the provisions of the NEC contract and was managed within the overall budget for construction works. The new storage tank was integrated from an ICA perspective by linking to NI Water’s telemetry system for effective monitoring of storage levels and overflow incidents.

Throughout construction, regular site inspections were undertaken by Tetra Tech’s Site Supervisor and Health & Safety Manager to affect joint inspections with NI Water’s and MDW’s H&S Managers. This made sure of a combined approach to H&S management; issues were addressed face to face in real time and resulted in an excellent H&S performance throughout, with no accidents or incidents.

Early contractor involvement (ECI)

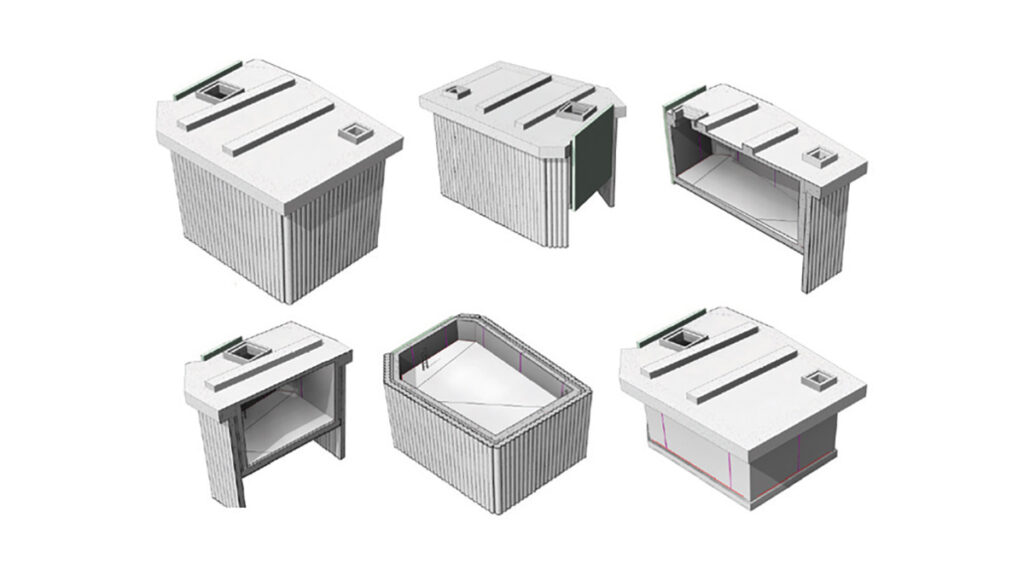

The ECI process proved its worth as extensive design and build challenges were overcome and a buildable solution was developed that satisfied the construction brief and costs criteria. This led to Murphy/DAWSON-WAM Ltd being appointed as principal contractor for the design and build of Lower Woodburn WwPS upgrade in August 2023. Contract works involved the design, supply, installation, testing and commissioning of an additional 317m3 of additional gravity storm storage on the existing site.

Certain elements of the project proved extremely challenging, none less than the design and construction of the additional storage tank on an existing site footprint that was extremely compact. Construction was further restricted as access to the site was from the busy A2 road, (the main road corridor from Belfast to Carrickfergus), immediately to the east of the site was a live petrol station with underground fuel tanks, on the west was an existing domestic occupied property and the access to the property and to the local strand, straddled the site on the east and south side. This was further complicated by the fact the existing pumping station had to be kept operational during the entire construction process.

The extensive ECI (which included site investigations, topographical surveys, network modeling, liaison with key stakeholders and utility providers, design development and costs approval), was completed post contract award. MDW appointed RPS as their civil design partner and through collaboration with NI Water and Tetra Tech, overcame the buildability challenges of this compact site.

The ground investigation report undertaken on the footprint of the only available space on the site identified glacial till overlying bedrock which varied from 6 to 8m below ground level. Early tank storage design calculations indicated that a tank depth of approximately 6.1m deep below ground level would maximise the footprint available within NI Water’s site, and enabled a gravity return into the existing pumping station.

Temporary works

Several temporary works solutions were considered to facilitate the tank construction including the use of a steel sheet pile cofferdam. This solution was omitted for several reasons but predominately because of the vibration risk to the surrounding properties and being unable to achieve sufficient embedment into the mudstone bedrock.

For the solution, DAWSON-WAM Ltd developed a secant piled cofferdam design which deployed a hard/hard continuous flight auger with reinforcement cages in every male pile (second pile). Utilising a double auger drive motor, it was capable of coring into the mudstone while maintaining pile verticality.

Working with piling design partner, Cassidy Geotechnical Ltd, a 450mm diameter secant piled cofferdam with 9m long piles was developed as the most viable solution. This was further valued engineered by incorporating the piles as part of the permanent works and introducing a single face, in situ, internal reinforced concrete lining to form the internal wall of the tank. Through design analysis, it was identified in the temporary condition the secant piled cofferdam would require propping during excavation, but this was omitted by collaboration between the piling designer and contractor by introducing a reinforced capping beam that was poured prior to excavation which reduced the deflection enough during excavation to eliminate the requirement of the temporary prop. The capping beam would also provide support the permanent in-site reinforced roof structure.

Pre-construction structural surveys were undertaken on all the surrounding properties and vibration monitors were installed at two locations adjacent to the site during piling operations. The secant method proved a success as the piles were installed to the designed length without triggering any vibration limits and when excavated provided a watertight cofferdam.

Construction

Due to the storage requirements of the tank, and given the small site footprint, there was not adequate space on the site to undertake the construction works safely. Therefore, a detailed construction phasing plan was developed by the contractor at the ECI stage which incorporated keeping the existing pumping station in service during construction.

This plan identified that by temporarily incorporating the existing access lane (leading to the beach and neighbouring property) as part of the site, construction could be undertaken. An agreement was reached with the owners of the house – who had just recently purchased the property – to delay their relocation to the dwelling until works had been completed, and the council agreed to temporarily close access to the strand to aid construction.

Solution

Add text here

Result

Add text here

Client

Location

Design Engineer

Main Contractor